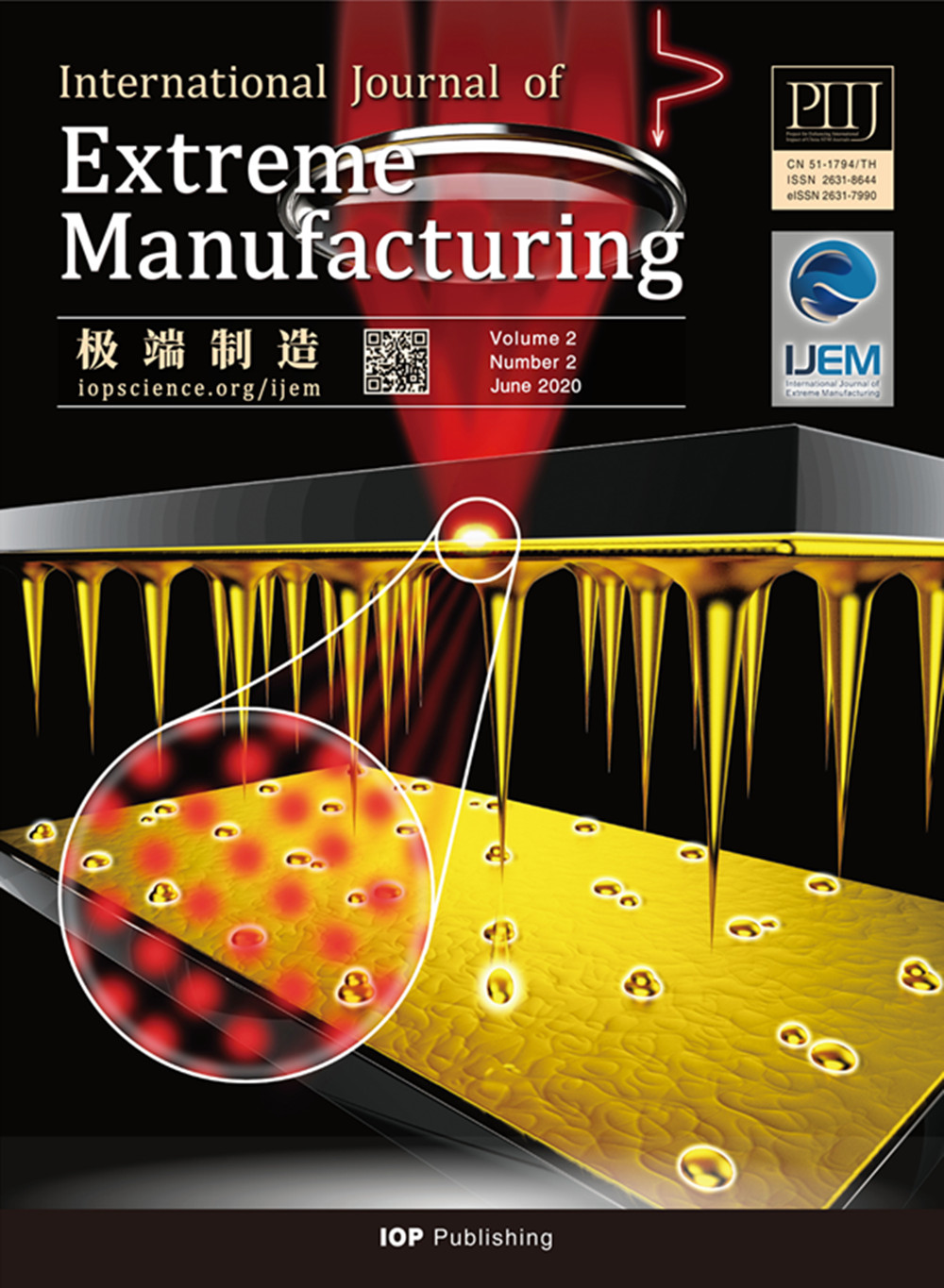

Atomic level deposition to extend Moore's law and beyond

doi: 10.1088/2631-7990/ab83e0

- Publish Date: 2020-04-03

-

Key words:

- Moore’s law /

- atomic level deposition /

- high resolution /

- selective deposition /

- alignment

Abstract:

In the past decades, Moore's law drives the semiconductor industry to continuously shrink the critical size of transistors down to 7 nm. As transistors further downscaling to smaller sizes, the law reaches its limitation, and the increase of transistors density on the chip decelerates. Up to now, extreme ultraviolet lithography has been used in some key steps, and it is facing alignment precision and high costs for high-volume manufacturing. Meanwhile, the introduction of new materials and 3D complex structures brings serious challenges for top-down methods. Thus, bottom-up schemes are believed to be necessary methods combined with the top-down processes. In this article, atomic level deposition methods are reviewed and categorized to extend Moore's law and beyond. Firstly, the deposition brings lateral angstrom resolution to the vertical direction as well as top-down etching, such as double patterning, transfer of nanowires, deposition of nanotubes, and so on. Secondly, various template-assisted selective deposition methods including dielectric templates, inhibitors and correction steps have been utilized for the alignment of 3D complex structures. Higher resolution can be achieved by inherently selective deposition, and the underlying selective mechanism is discussed. Finally, the requirements for higher precision and efficiency manufacturing are also discussed, including the equipment, integration processes, scale-up issues, etc. The article reviews low dimensional manufacturing and integration of 3D complex structures for the extension of Moore's law in semiconductor fields, and emerging fields including but not limited to energy, catalysis, sensor and biomedicals.

1d1aca63-f97d-4140-83d4-c3b25976ef17.jpg)

DownLoad:

DownLoad: